Welcome all importer

TANGRAM STUDIO CO., LTD. is a manufacturer, exporter and distributer of Waste water treatments equipments, such as cross flow media, moving bed media and other items. TANGRAM STUDIO CO., LTD. has successfully erected and commissioned many waste water treatment equipment.

Our products

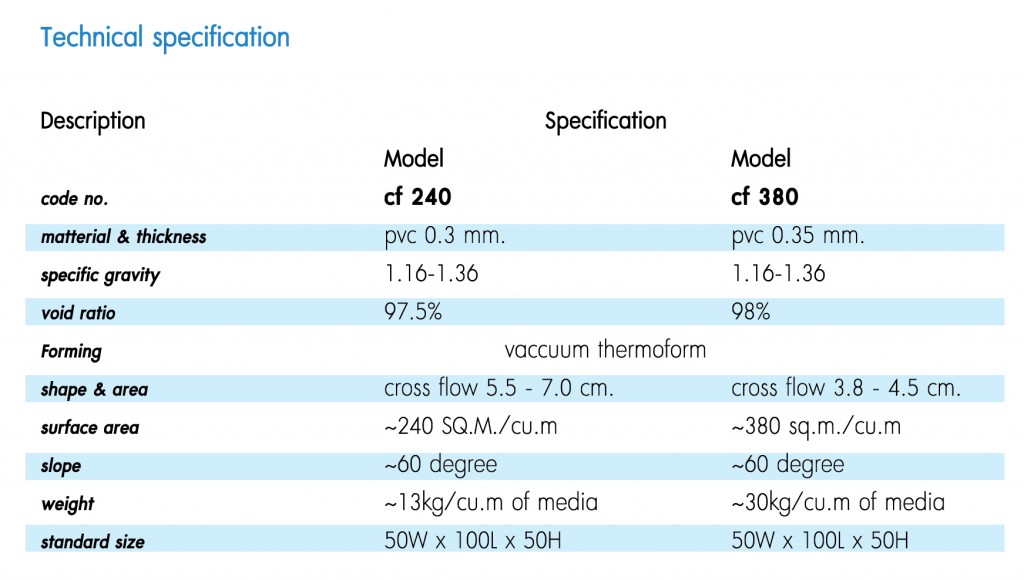

Cross Flow Media

Cross Flow Media is specifically designed for biological fixed film systems. Cross flow media provides a cost-effective method for reduction of organics (roughing and polishing), nitrification, denitrification, and anaerobic treatment of municipal and industrial wastewaters. The modules are fabricated from rigid PVC sheets, which are UV-protected and resistant to rot, fungi, bacteria, acids, and alkalis commonly present in municipal wastewater.

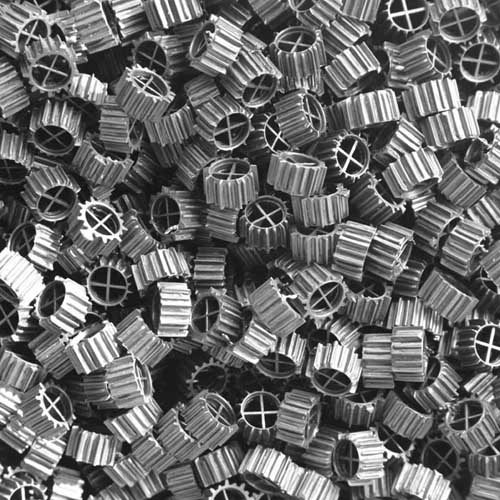

Moving bed media

Moving bed media processes are based on attached growth biofilm principles of biological wastewater treatment. The core of the processes is the biofilm carrier elements or media. While the biofilm is fixed to the media, the media is thoroughly mixed within a reactor and retained in the reactor. In a Moving bed media application all the biomass is attached on the media and retained in the biological reactor, so there is no return sludge

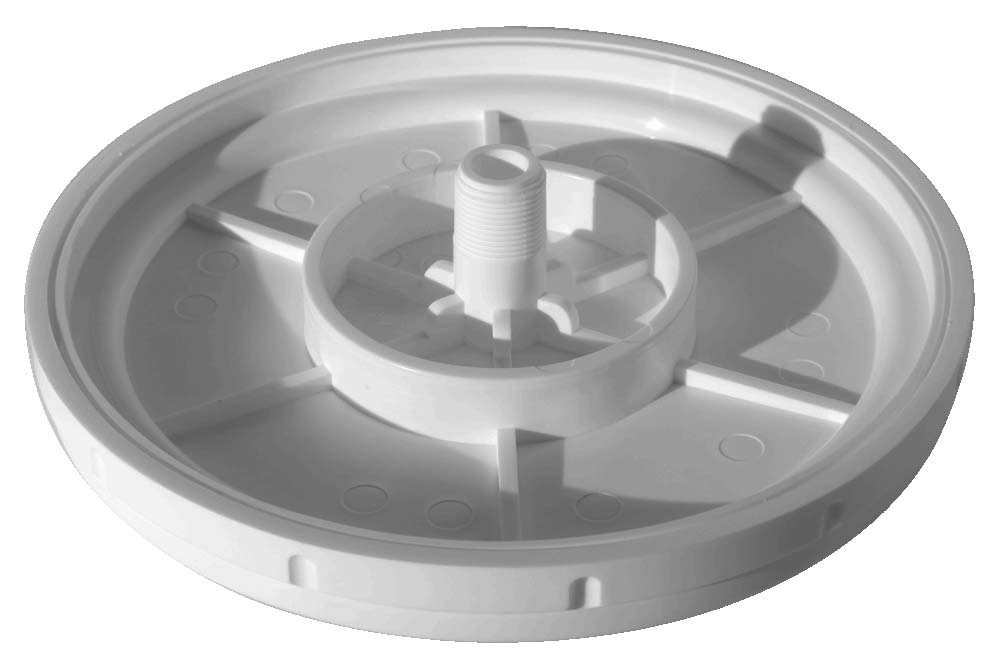

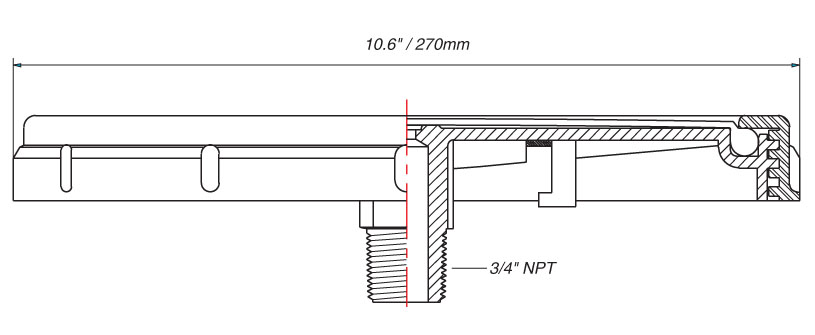

Air diffuser disc

We manufacture our disc diffusers with compression molded membranes. Standard materials are EPDM and fluoroelastomer layered EPDM. Compression molding ensures that we produce a part with even specific gravity and uniform tear resistance. Other molding techniques such as injection molding produce similar looking parts, but the tear resistance of a compression molded part is multidirectional, whereas the tear resistance of an injection molded part tends to be unidirectional just like wood which has a grain.

There is an art to using just the right amount of plasticizer in an EPDM membrane. Use too much, or the wrong type, and emulsifying fats can leech plasticizer and cause shrinkage and increase hardness. Use too little, and the rubber loses its memory, bubble size increases, and the membrane is at risk for flexure failure. We have had a great deal of experience experimenting with different types and amounts of plasticizer, as well as other components of formulated EPDM rubber, such as fillers and curatives, and we put this experience to work. Membrane perforation and surface charge are additional considerations. The YKH10 perforates disc membranes from the inside out with specially shaped knives. This results in the smallest part of the perforation on the membrane surface where the bubble is released. Through proprietary compounding and surface treatments, we are able to create a smooth perforation on a hydrophilic surface which quickly releases small bubbles, typically from 1 to 2 mm in diameter. The YKH10 uses environmentally friendly materials whenever possible. Our disc diffuser parts are predominantly made of polypropylene, which offers the added benefit of high temperature resistance to 212 F (100C)

THANK YOU FOR YOUR INTERESTING OUR PRODUCTS.

….. If you have any question , please feel free to contact us, Pls email to : tangramstudio@yahoo.com ….